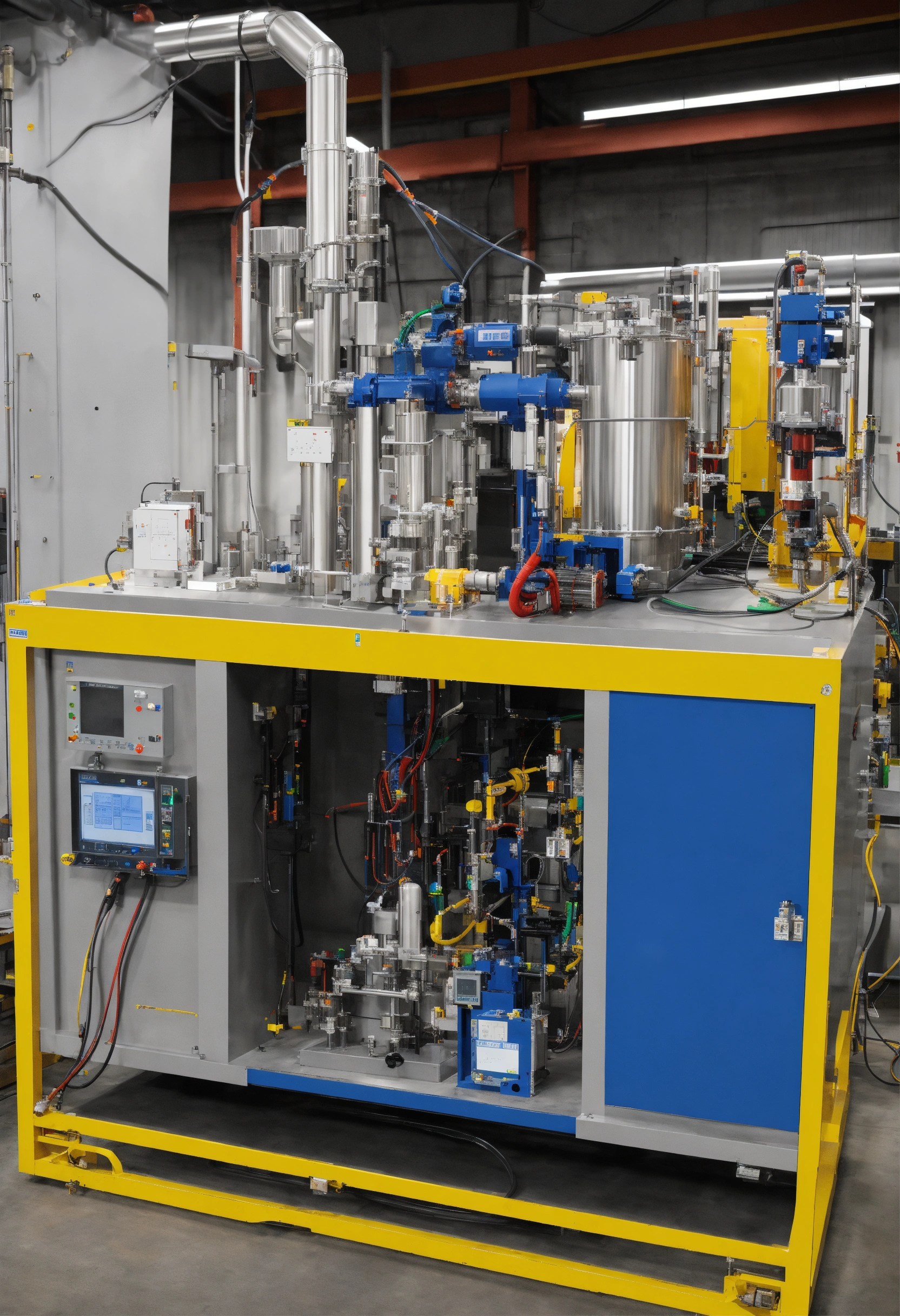

This involves the installation of a liquid silane injection system at the material input of a plastic extruder. the system will include a silane transfer cabinet with atex certification, stainless steel and polyamide pipes for the nitrogen station, a pneumatic barrel pump, a dosing station with a servo motor coupled to a precision gear pump, control via a plc, and a siemens touch screen hmi. additionally, it will involve the manufacturing of a variable-speed agitator for integration into the lower chute of the plastic resin hopper.

Copy prompt

Copy URL

Open in editor

Model

Aperture v3.5

Dimensions

832 × 1216